The entry to the competition!

Almost every user has breathed the taste of oil in their compressed air.

The increased concentration of pollutants is usually manifested by headaches during prolonged breathing activity and by dizziness or even unconsciousness at higher concentrations of pollutants.

Every year there are many injuries and deaths worldwide (especially in the diving industry) due to CO poisoning.

CO2which is often wrongly described as non-toxic can cause the above-mentioned symptoms at higher concentrations.

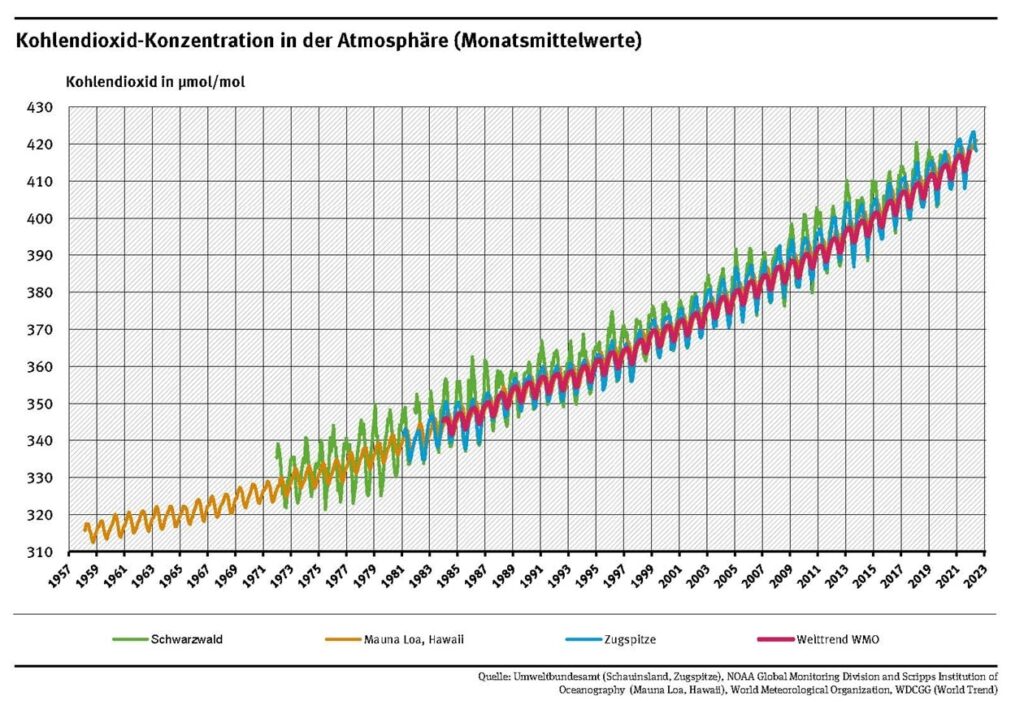

When IDE started operations over 30 years ago, CO2 The values were between 270 and 320 ppm and around 100 ppm higher in the cities. The limit value at the time was 1000 ppm.

[presto_player id=2856]

Today we have 350 - 450 ppm in the countryside and between 550 -800 ppm in the cities. The permissible limit value today has been 500 ppm since 2014.

For over a hundred years (test tubes were invented in 1919), fire departments, divers and industry have been testing air quality with so-called test tube tests, which leave a lot of room for interpretation due to the color display and usually have a standard deviation of 15 - 20%. They are also subject to a strong ageing process.

To make matters worse, this is only ever a snapshot in time.

Just one minute later, the air quality may have changed for whatever reason and nobody notices. Monitoring the filter saturation and humidity by means of a sensor in the filter cartridge is also no longer up to date as the sole safety device according to the state of the art and IDE's understanding of quality.

DIN EN 12021: 2014

Our answer: AIRSAVE ULTIMATE

The European standard DIN EN 12021:2014 is not an optional provision, but absolutely mandatory.

If you read the standard and some international standards carefully, it is not sufficient to determine the content of pollutants with the test tubes that have been used for decades, as according to today's technical understanding these are at best indicators and no longer suitable measuring instruments.

Euronorm 12021:2014 requires every operator of a filling station to ensure that the breathing air meets the values specified in the standard. at any time fulfilled.

A periodic snapshot using test tubes is therefore no longer enough.

IDE-Compressors is aware of its responsibility as a manufacturer of breathing air compressors and is the only company to supply air quality monitoring integrated into the compressor AIRSAVE ULTIMATE. We have been equipping all stationary professional compressors in the IDE line with the new online air quality monitoring system with HMI and touchscreen as standard for several years now.

The content of CO2, CO, O2, water in mg/m3, the temperature, the saturation of the dryer cartridge and optionally also NO, NO2 and SO2 and combustible gases are tested every 2 seconds in the compressed air after the dryer/filter with the highest quality longlife sensors used and tested in science with narrowly limited measuring ranges to ensure accurate measurements over a long period of time (No short-lived smart sensors).

Another option is the measurement of oil, with IDE-COMPRESSORS as the only breathing air compressor manufacturer also residual oil, especially in aerosol form (droplet form) up to a content of 0.001 mg/m3.

The new version of DIN EN 12021: 2014 is somewhat clearer and also refers to DIN 8573 for residual oil. For compliance with DIN EN 12021:2014 and DIN 8573 (medical air). The VOC volatile organic compounds (measurement with inexpensive PID sensors) is not sufficient as they cannot measure aerosols.

As a further option, there is a second sensor unit that analyzes the intake air for CO, CO2, NO, NO2, temperature and combustible gases before it enters the compressor and controls the compressor accordingly.

All measured values are stored in the system and can be retrieved via a USB or LAN interface as an EXCEL-capable file. Optionally, the values can also be transferred to your smartphone using the IDE ULTIMATE APP. Only a system of this type can really ensure that the filling system delivers pure breathing air in accordance with DIN EN 12021:2014 and other standards at all times and that the operator is never exposed to an accident or even liability risk.